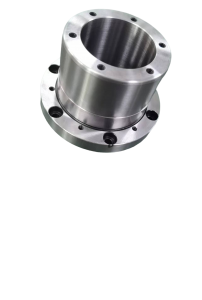

CNC tig Custom fabrication Aluminium, stainless hlau, Precise machining qhov Precision machining

Product Description

Cov cuab yeej ua haujlwm cnc milling tshuab / CNC tshuab dhos / sib tsoo tshuab / milling tshuab / tshuab dhos / hlau txiav thiab lwm yam.

Customizable khoom Aluminium alloy:

5052/6061/6063/6065/2017/7075 thiab lwm yam.

Brass Alloy:

3602/2604/H59/H62 thiab lwm yam.

Stainless hlau Alloys:

303/304/316/412/440C thiab lwm yam.

Carbon Steel Alloys:

Carbon steel / tuag steel, thiab lwm yam.

Peb tuav ntau hom khoom siv.Yog tias koj xav tau cov ntaub ntawv tsis tau teev saum toj no, thov hu rau peb.

Kev kho deg Blackened, Polished, Anodized, Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Kev tshuaj xyuas qhov siab ntsuas, ntsuas hniav, ntsuas qhov ntsuas video, ntsuas peb-dimensional ntsuas, thiab lwm yam.

Cov ntaub ntawv tawm tswv yim AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, SolidWorks, thiab lwm yam.

Koj puas tuaj yeem muab kev kho saum npoo rau precision machined qhov chaw?

Peb muab ntau hom kev kho deg rau cov khoom siv siab precision.Qee qhov kev ua tiav no suav nrog sandblasting, txhuam hniav, electroplating thiab electroplating, passivation, anodizing, chrome plating, polishing, thiab lwm yam.Cov khoom tiav no tiv thaiv cov khoom los ntawm cov xwm txheej hnyav, txhim kho ib feem ntawm kev ua haujlwm lossis txhim kho nws qhov zoo nkauj.

Kuv yuav ua li cas thiaj paub tias kuv cov qauv tsim yuav raug zais cia?(Daim ntawv cog lus tsis pub lwm tus paub)

Nrog lub koob npe nrov rau kev ua haujlwm nrog ntau pua txhiab tus qauv tsim tshwj xeeb hauv lub xyoo, peb ib txwm khaws cov ntaub ntawv ntawm cov neeg siv khoom tsis pub lwm tus paub thiab muaj cov cai nruj nyob hauv peb cov chaw tsim khoom.Yog tias xav tau, peb tuaj yeem kos npe NDAs nrog cov neeg siv khoom xav tau daim ntawv no

Yuav ua li cas kuv thiaj li tau txais ib daim ntawv cog lus tsim khoom?

1. Upload koj cov ntaub ntawv CAD

Thawj kauj ruam yog ua kom yooj yim sau koj cov ntaub ntawv thiab upload koj cov ntaub ntawv CAD.Qhov no pab peb tsim 3D qauv ntawm qhov xav tau ib feem lossis qauv.

2. Cov lus hais thiab tsim kev tsom xam

Hauv 12 teev, peb yuav muab cov lus qhia thiab DFM rau koj.Qhov no ua kom koj qhov project tuaj yeem ua tiav thiab muab koj tus nqi kwv yees raug.

3. Order thiab pib ntau lawm

Thaum koj tau pom zoo koj qhov kev tsocai thiab tsim, peb yuav pib tsim koj tus qauv CNC lossis CNC machined ib feem khoom.

4. Nkoj thiab tau txais koj qhov chaw

CNC machined qhov chaw lossis cov khoom yuav raug tsim nyob rau hauv hnub.Peb xa tuaj rau koj los ntawm kev nthuav qhia thoob ntiaj teb.Thov koj xav tias dawb muab cov lus qhia rau peb kom paub tseeb tias lawv ua tau raws li koj qhov kev cia siab.

High-quality precision machining yuav tsum muaj peev xwm nthuav dav thiab ua raws li cov qauv tshwj xeeb los tsim cov khoom lag luam zoo.Thaum nrhiav cov txiaj ntsig zoo, ua haujlwm nrog lub tuam txhab txhim khu kev qha precision machining yog qhov tseem ceeb.Peb muab ntau yam ntawm precision machining cov kev pab cuam xws li precision tig, milling, thiab EDM kom tau raws li koj cov kev xav tau zoo.

Los ntawm cov qauv mus rau ntau lawm, los ntawm 1 daim mus rau 10,000 daim, peb muab ceev ceev turnaround CNC machining rau koj cov kev cai hlau thiab yas qhov chaw, nrog rau tus me nyuam sai li 3 hnub.

Peb tuaj yeem tsim cov khoom siv high-precision nrog qhov ntev ntev ntawm ± 0.01 hli, geometrical kam rau ua ntawm 0.01 hli, qhov tsawg tshaj plaws machining vojvoog ntawm R0.1 hli, thiab machining nto roughness ntawm Ra0.2μm.Peb kuj feem ntau sib tw qhov chaw kho qhov muag nrog cov ntsiab lus meej.

Dab tsi ntawm qhov chaw tiav ua CNC machining tawm tom qab?

Tom qab cov txheej txheem machining tiav, qhov saum npoo ntawm CNC feem yuav muaj cov cuab yeej pom me ntsis, hu ua "raws li machined" lossis "raws li machined" nto tiav.Machined nto roughness (Ra) yog normalized rau 1.6-3.2 μm, thiab nto tiav yuav tsum tau nce mus rau 0.8-1.6 μm los yog siab dua ntawm 0.2-0.8 μm, tab sis qhov no yuav tsum tau ntau lub sij hawm ua hauj lwm thiab tus nqi siab dua.

Koj lub sijhawm xa khoom yog dab tsi?

Qhov tseeb, tsis muaj lub sijhawm xa khoom raws sijhawm, peb yuav teem sijhawm ntau lawm raws li cov haujlwm tam sim no.Thaum koj tau txais daim ntawv xaj khoom, cov ntaub ntawv tiav, thiab cov ntaub ntawv npaj tau, peb yuav muab cov lus qhia tam sim ntawm lub sijhawm xa khoom, uas feem ntau yog nyob ntawm 3 hnub ua haujlwm mus rau ob peb lub lis piam, nyob ntawm qhov nyuaj ntawm qhov thiab qhov ntau ntawm cov khoom xaj. .