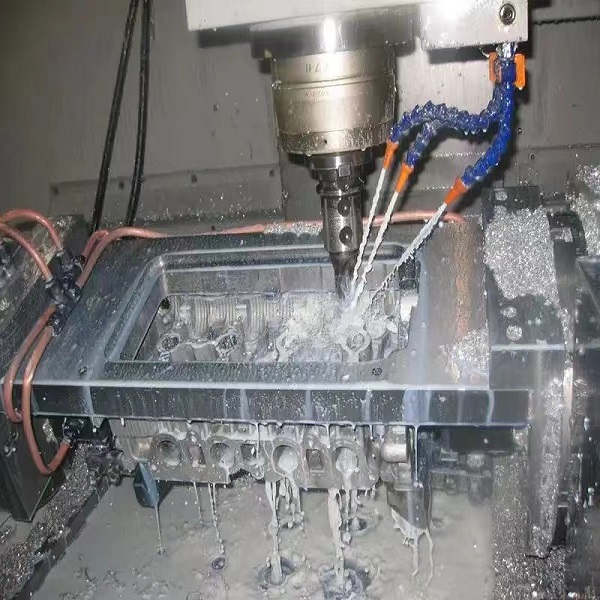

CNC milling kev pab ua, bearing pedestal, milling qhov chaw

Product Description

Cov cuab yeej ua haujlwm cnc milling tshuab / CNC tshuab dhos / sib tsoo tshuab / milling tshuab / tshuab dhos / hlau txiav thiab lwm yam.

Customizable khoom Aluminium alloy:

5052/6061/6063/6065/2017/7075 thiab lwm yam.

Brass Alloy:

3602/2604/H59/H62 thiab lwm yam.

Stainless hlau Alloys:

303/304/316/412/440C thiab lwm yam.

Carbon Steel Alloys:

Carbon steel / tuag steel, thiab lwm yam.

Customizable khoom Aluminium alloy:

5052/6061/6063/6065/2017/7075 thiab lwm yam.

Brass Alloy:

3602/2604/H59/H62 thiab lwm yam.

Stainless hlau Alloys:

303/304/316/412/440C thiab lwm yam.

Carbon Steel Alloys:

Carbon steel / tuag steel, thiab lwm yam.

Peb tuav ntau hom khoom siv.Yog tias koj xav tau cov ntaub ntawv tsis tau teev saum toj no, thov hu rau peb.

Kev kho deg Blackened, Polished, Anodized, Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Kev tshuaj xyuas qhov siab ntsuas, ntsuas hniav, ntsuas qhov ntsuas video, ntsuas peb-dimensional ntsuas, thiab lwm yam.

Cov ntaub ntawv tawm tswv yim AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, Solidworks, thiab lwm yam.

Customizable khoom xav tau:

| Lub npe qhov project | Aluminium 6061, Stainless hlau, tooj dag, siab precision hlau qhov chaw |

| Cov cuab yeej ua haujlwm | CNC milling tshuab / CNC tshuab dhos / zeb / milling tshuab / tshuab dhos / hlau txiav, thiab lwm yam |

| Customizable khoom salufer: | Aluminium: 5052/6061/6063/2017/7075, thiab lwm yam Copper Alloy: 3602/2604/H59/H62 et al stainless hlau alloy: 303/304/316/412 et al hlau: Carbon steel / tuag steel / thiab lwm yam Peb suav nrog ntau hom khoom siv.Yog tias cov ntaub ntawv koj xav tau tsis tau teev saum toj no, thov hu rau peb. |

| Kev kho saum npoo | dub, polished, anodized, chrome plated, galvanized, npib tsib xee plated, xim |

| Kev kos duab | AutoCAD (DXF, DWG), PDF, TIF, thiab lwm yam. |

Quality Assurance:

High quality precision machining yuav tsum tau kev txawj ntse ntxiv thiab cov ncauj lus kom ntxaws ua raws li cov qauv tshwj xeeb txhawm rau tsim cov khoom tshwj xeeb.Kev koom tes nrog lub tuam txhab txhim khu kev qha precision machining yog qhov tseem ceeb thaum nrhiav cov txiaj ntsig zoo.Peb muab ntau yam kev pabcuam precision machining, suav nrog precision tig, milling thiab EDM kom tau raws li koj cov kev xav tau zoo.

Los ntawm cov qauv mus rau ntau lawm, los ntawm 1 mus rau 10,000 daim, peb muab ceev ceev turnaround CNC machining rau koj cov kev cai hlau thiab yas qhov chaw nrog me me li 3-hnub tus me nyuam

Peb tuaj yeem tsim cov khoom siv siab precision nrog qhov ntev ntev ntawm ± 0.01mm, geometric tolerances ntawm 0.01mm, yam tsawg kawg nkaus tshuab radii ntawm R0.1mm, thiab machined nto roughness ntawm Ra0.2μm.Peb kuj feem ntau sib tw qhov chaw kho qhov muag nrog cov ntsiab lus meej.

CNC milling

Nrog rau txoj kev loj hlob sai ntawm kev tshawb fawb thiab thev naus laus zis, tib neeg ntawm cov qauv ntawm cov khoom siv tshuab, kev ua tau zoo, qhov tseeb, kev ua tau zoo thiab ntau yam ntawm cov kev xav tau nce siab, qhov feem ntawm ib qho khoom me me thiab nruab nrab ntau ntxiv.Ib txwm siv lub hom phiaj, cov cuab yeej siv tshuab tshwj xeeb thiab cov txheej txheem cov cuab yeej siv tsis tau zoo raws li cov kev xav tau ntawm kev ua haujlwm siab, kev ua haujlwm siab, kev ua ntau yam.

CNC tshuab cuab yeej raws li kev sib txuas ntawm cov ntaub ntawv siv tshuab hluav taws xob thiab cov cuab yeej siv tshuab ib txwm siv, kev sib xyaw ua ke ntawm cov tshuab niaj hnub precision, khoos phis tawj, kev sib txuas lus, hydraulic pneumatic, optoelectronics thiab lwm yam kev siv tshuab ntau yam, zoo daws qhov nyuaj, meej, me me batch ntawm qhov sib txawv. ua cov teeb meem, kom tau raws li qhov zoo, siab efficiency thiab ntau hom, me me batch ntawm saj zawg zog ntau lawm yuav tsum, hloov mus rau cov kev xav tau ntawm ntau yam khoom siv kho tshuab hloov kho sai Nws sawv cev rau cov qauv thiab qauv ntawm niaj hnub machining tshuab.

CNC milling qhov chaw

Koj lub sijhawm xa khoom yog dab tsi?

Qhov tseeb, tsis muaj lub sijhawm xa khoom raws sijhawm.Peb yuav teem sijhawm ntau lawm raws li cov haujlwm tam sim no.Thaum koj tau txais daim ntawv xaj khoom, cov ntaub ntawv tiav, thiab cov ntaub ntawv npaj tau, peb yuav muab cov lus qhia tam sim ntawm lub sijhawm xa khoom, uas feem ntau yog nyob ntawm 3 hnub ua haujlwm mus rau ob peb lub lis piam, nyob ntawm qhov nyuaj ntawm qhov thiab qhov ntau ntawm cov khoom xaj. .

FQA

Peb cov nqi yuav raug hloov raws li cov khoom siv thiab lwm yam kev lag luam.Peb yuav xa koj daim ntawv teev nqi tshiab tom qab koj lub tuam txhab tiv tauj peb kom paub ntxiv.

Yog lawm, peb xav kom txhua qhov kev txiav txim thoob ntiaj teb kom muaj qhov kev txiav txim yam tsawg kawg nkaus.Yog tias koj tab tom nrhiav rov muag tab sis hauv ntau qhov me me, peb xav kom koj mus saib peb lub vev xaib.